The Challenge

Warcola Honey Farms needed to monitor honey levels in remote storage tanks spread across their facility. Manual checking risked overflow (losing product) or running empty (halting production). They needed 24/7 automated monitoring that could survive harsh outdoor conditions.

System Requirements

- Monitor 3 tanks up to 500ft apart

- Survive -20°F to 100°F temperature range

- Run 45+ days on battery power

- Less than 1% data loss acceptable

- Real-time alerts for critical levels

Technical Architecture

Hardware Design

5-Node ESP32 Mesh Network:

- 3x Tank Sensor Nodes (ESP32 + Ultrasonic sensors)

- 1x Relay Node (Range extension + redundancy)

- 1x Gateway Node (WiFi bridge to cloud)

Power System:

- 18650 Li-Ion battery packs (3S2P configuration)

- Solar charging for gateway node

- Deep sleep optimization: 120-second cycles

- Current draw: 0.5mA sleep, 80mA active

Communication Protocol

Implemented custom ESP-NOW protocol with reliability layer:

typedef struct {

uint8_t node_id;

float tank_level;

float battery_voltage;

int8_t rssi;

uint32_t timestamp;

uint8_t crc8;

} SensorPacket;

// Reliability improvements

void sendWithRetry(SensorPacket* packet) {

for(int attempt = 0; attempt < MAX_RETRIES; attempt++) {

if(esp_now_send(gateway_mac, (uint8_t*)packet, sizeof(SensorPacket)) == ESP_OK) {

if(waitForAck(packet->node_id, ACK_TIMEOUT)) {

return; // Success

}

}

delay(BACKOFF_TIME * (1 << attempt)); // Exponential backoff

}

}Critical Bug: The 15% Problem

Initial deployment had 15% packet loss. Through systematic debugging:

- Channel Scanning: WiFi interference on channel 1

- Power Issues: Voltage drops during transmission

- Timing: Nodes transmitting simultaneously

Solution:

- Fixed WiFi channel (6)

- Added 1000µF capacitors

- Implemented TDMA-style time slots

- Custom CRC-8 validation

Result: Less than 0.1% packet loss over 2 months

Field Performance

📊 2-Month Deployment Stats:

- 99.94% Uptime (45 minutes total downtime)

- 0.08% Packet Loss (from 1.2M transmissions)

- 52 Days Battery Life (exceeded 45-day requirement)

- Zero False Alarms

- 2 Overflow Events Prevented

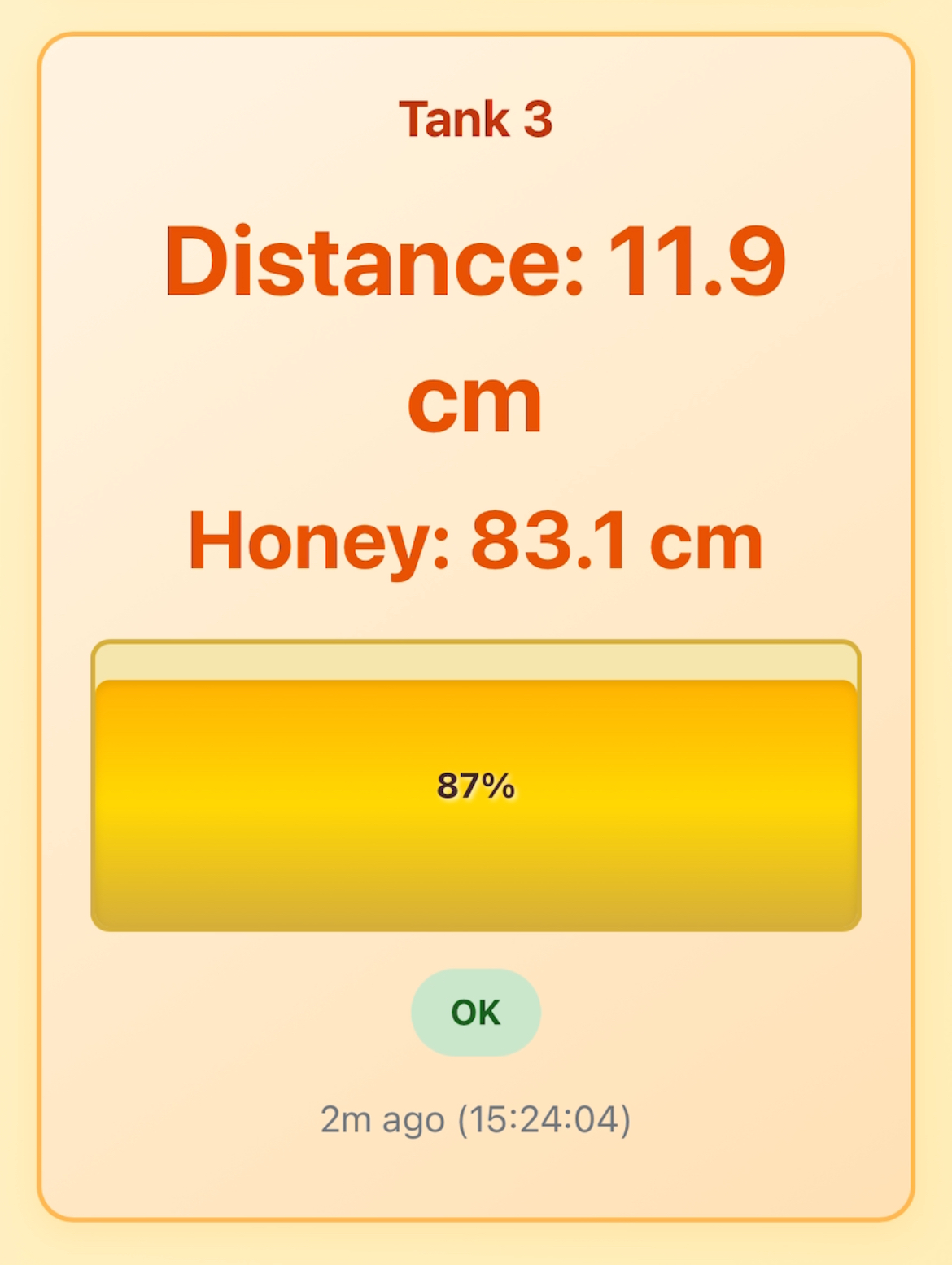

Dashboard & Monitoring

Built web dashboard with:

- Real-time tank levels

- Historical trending

- Battery health monitoring

- SMS/Email alerts for critical events

- Predictive “time until full/empty”

Harsh Environment Adaptations

- Enclosures: IP67-rated with desiccant packs

- Antennas: External high-gain antennas with lightning protection

- Temperature: Conformal coating on PCBs

- Mounting: Vibration-dampened mounts

Impact & Adoption

The system was so successful that Warcola:

- Adopted it as permanent infrastructure

- Requested expansion to 8 additional tanks

- Estimated ROI: 3 months from prevented losses

- Saved 10 hours/week of manual checking

Technical Deep-Dive

For the full technical documentation including:

- PCB designs and schematics

- Complete source code

- Deployment guide

- Grafana dashboard templates

Visit the GitHub Repository

What I Learned

This project taught me that embedded systems in the real world are 20% writing code and 80% solving environmental challenges. The “perfect” solution in the lab often fails in the field. Iterative testing and robust error handling made the difference between a demo and production-ready infrastructure.